Introduction

The packaging industry is transforming at a rapid pace. Driven by sustainability goals, rising consumer demand, and global market competition, paper container machinery manufacturers are innovating like never before.

At DABA Machinery, we believe that technological innovation is the foundation of competitiveness. From automation to sustainability, our R&D focuses on delivering advanced solutions that help clients achieve efficiency, consistency, and eco-friendly production.

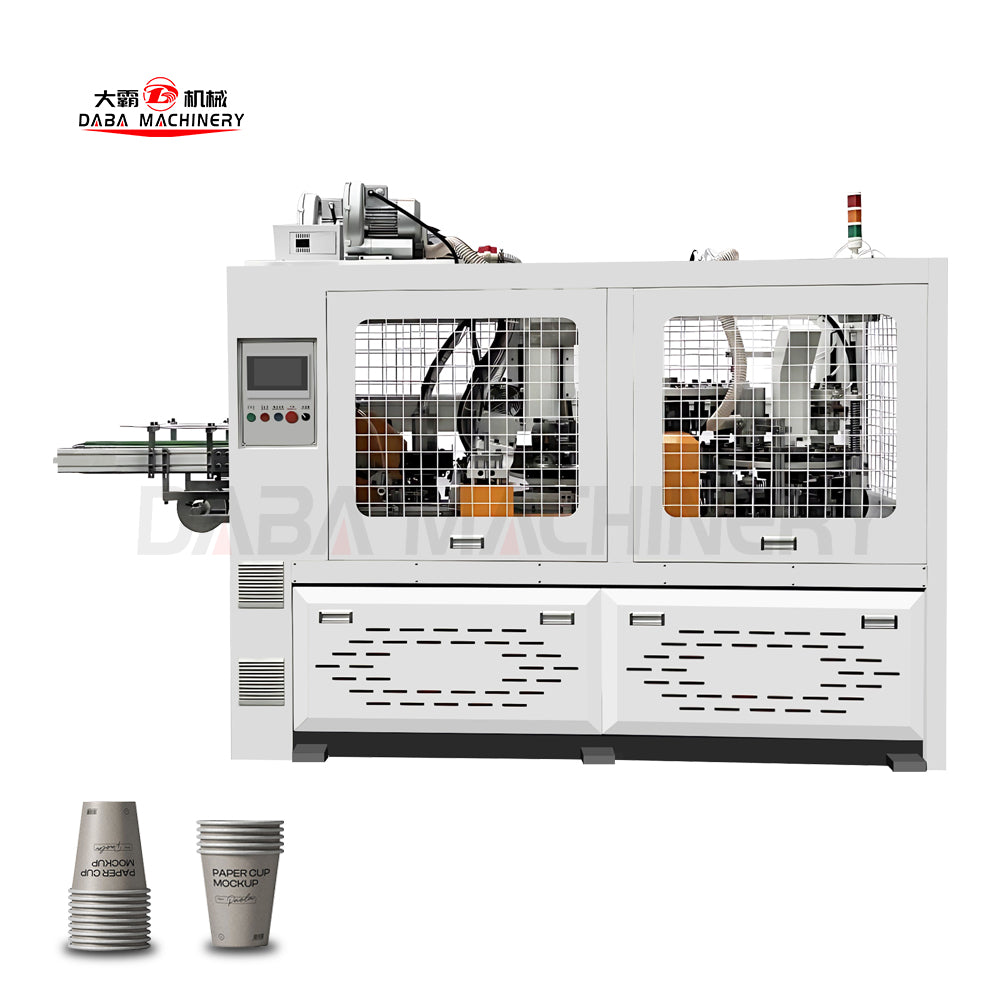

1. Automation and High-Speed Production

Modern businesses require both speed and reliability.

-

Automatic paper cup and bowl forming equipment ensures continuous high-volume production.

-

Servo-driven systems and PLC controls reduce downtime and improve accuracy.

-

Touchscreen interfaces make operation intuitive, minimizing training needs.

Result: Businesses can scale production seamlessly while reducing labor dependency.

2. Eco-Friendly and Energy-Saving Design

Sustainability is no longer optional—it’s essential.

-

Flexo printing machines use water-based inks that are safer for the environment.

-

Optimized heating systems reduce energy consumption.

-

Precision cutting and forming technology minimize paper waste.

This innovation allows companies to comply with global regulations while strengthening eco-conscious brand identity.

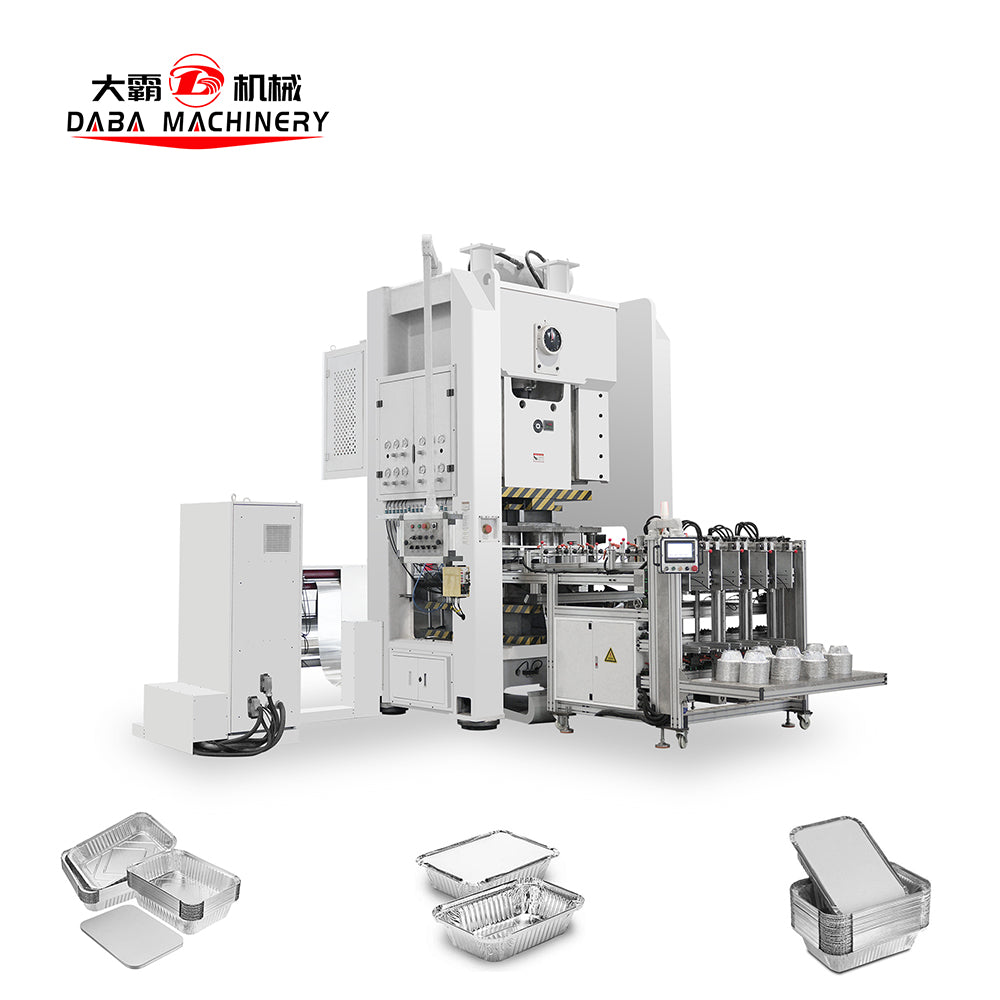

3. Multi-Functionality and Flexibility

The market demands versatility.

-

Machines support multiple cup and bowl sizes with quick mold changes.

-

Modular design allows for upgrades and customization.

-

One machine can adapt to various production requirements, reducing investment risk.

Flexibility ensures businesses stay competitive as consumer trends evolve.

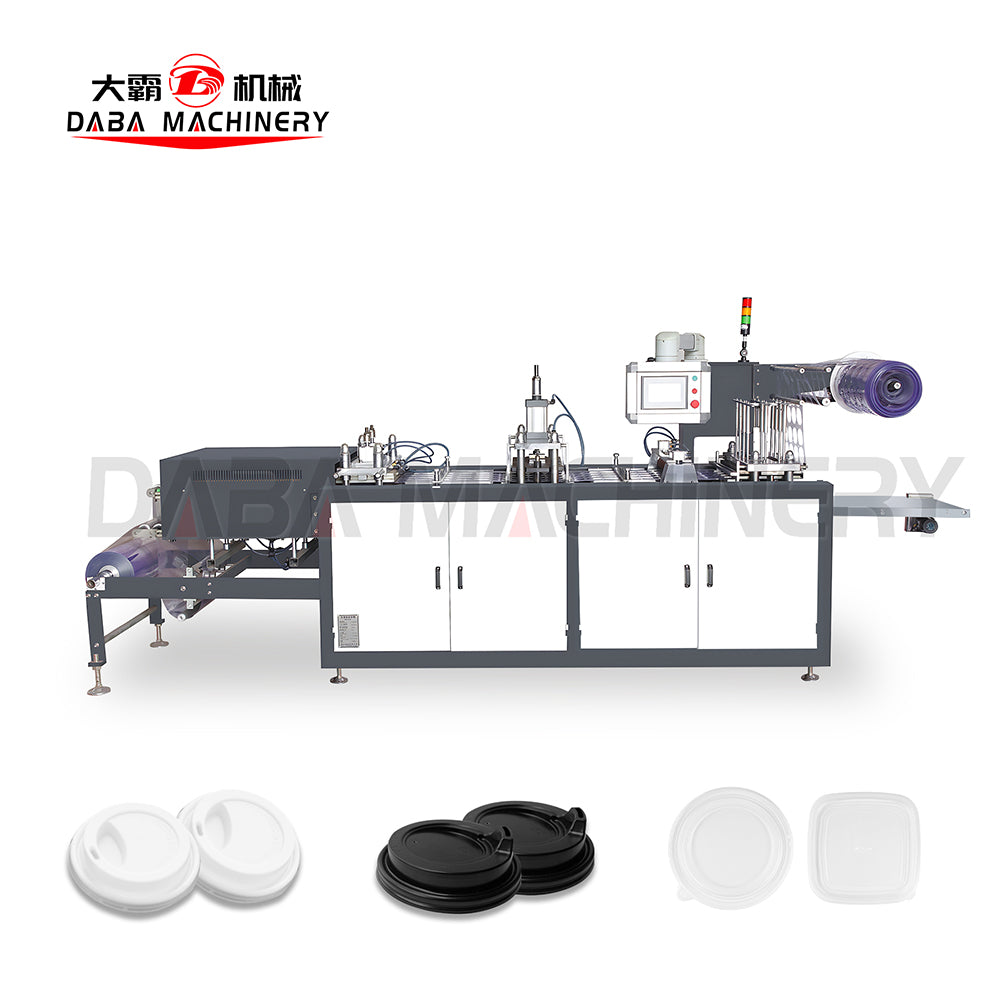

4. Smart Quality Control

Consistency is critical in packaging production.

-

Photoelectric sensors (tracking eye) ensure precise registration during printing and forming.

-

Counting sensors track output accurately, helping with order management and quality assurance.

-

Automatic error detection systems reduce misalignment and minimize waste.

These innovations ensure reliable, high-quality results across every production run.

5. Digitalization and Industry 4.0 Integration

The future of manufacturing is digital.

-

Data tracking allows managers to monitor output, energy use, and error rates.

-

Remote diagnostics and maintenance minimize downtime.

-

IoT connectivity helps integrate machinery into fully smart factories.

With these upgrades, paper container machinery becomes part of an intelligent, connected production ecosystem.

Conclusion

From automation to eco-friendly engineering, DABA Machinery is shaping the future of paper cup machines, automatic paper bowl forming equipment, and flexo printing solutions. Our commitment to continuous R&D ensures that clients gain not only advanced machinery but also long-term competitive advantages.

By embracing innovation, we help businesses worldwide meet efficiency goals, reduce environmental impact, and thrive in a rapidly changing market.