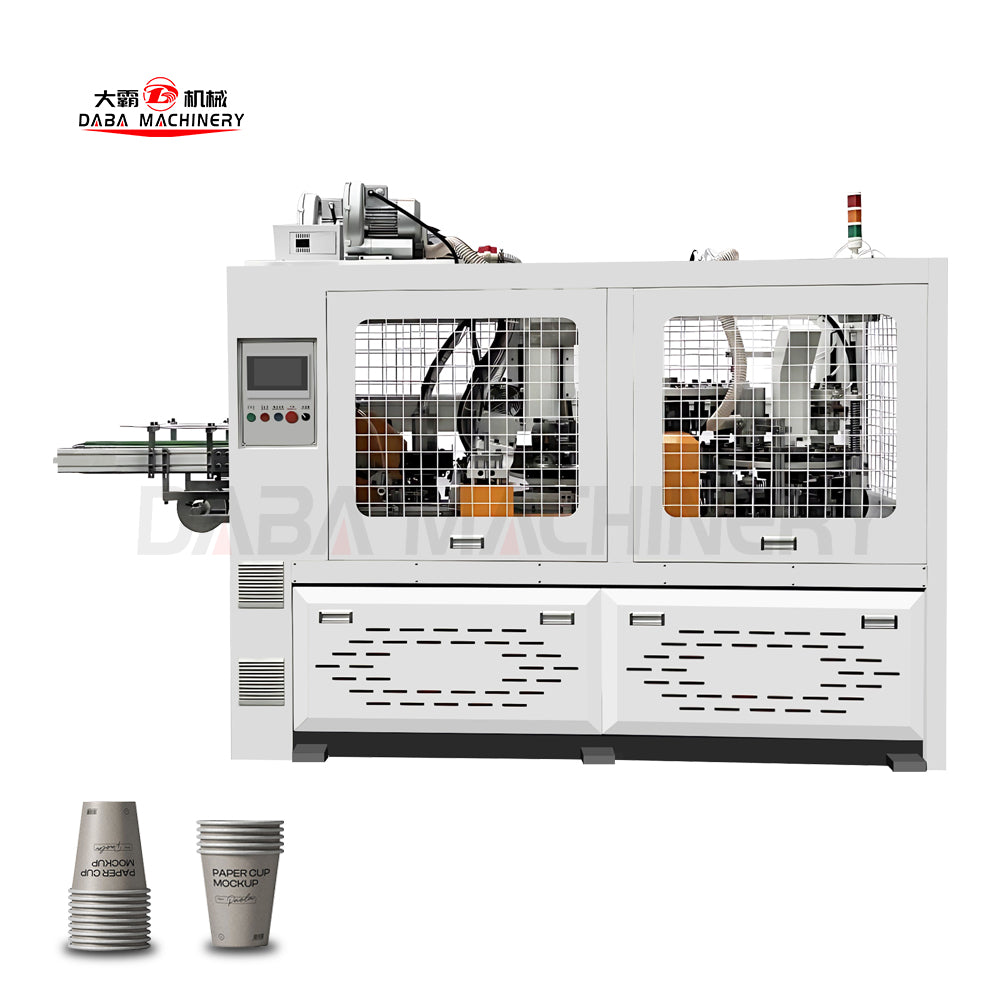

DBSF-B138-120 Four Servo Paper Cup Machine

Contact our support team via phone or WhatsApp:

📞 +86 136 4655 1968

Covers key components and technical support for 12 months.

🛠️ 1-Year Manufacturer Warranty

Description

Machine Description

Machine Structure

Product Size

Features/Functions

Sample Display

Video

Production Flow

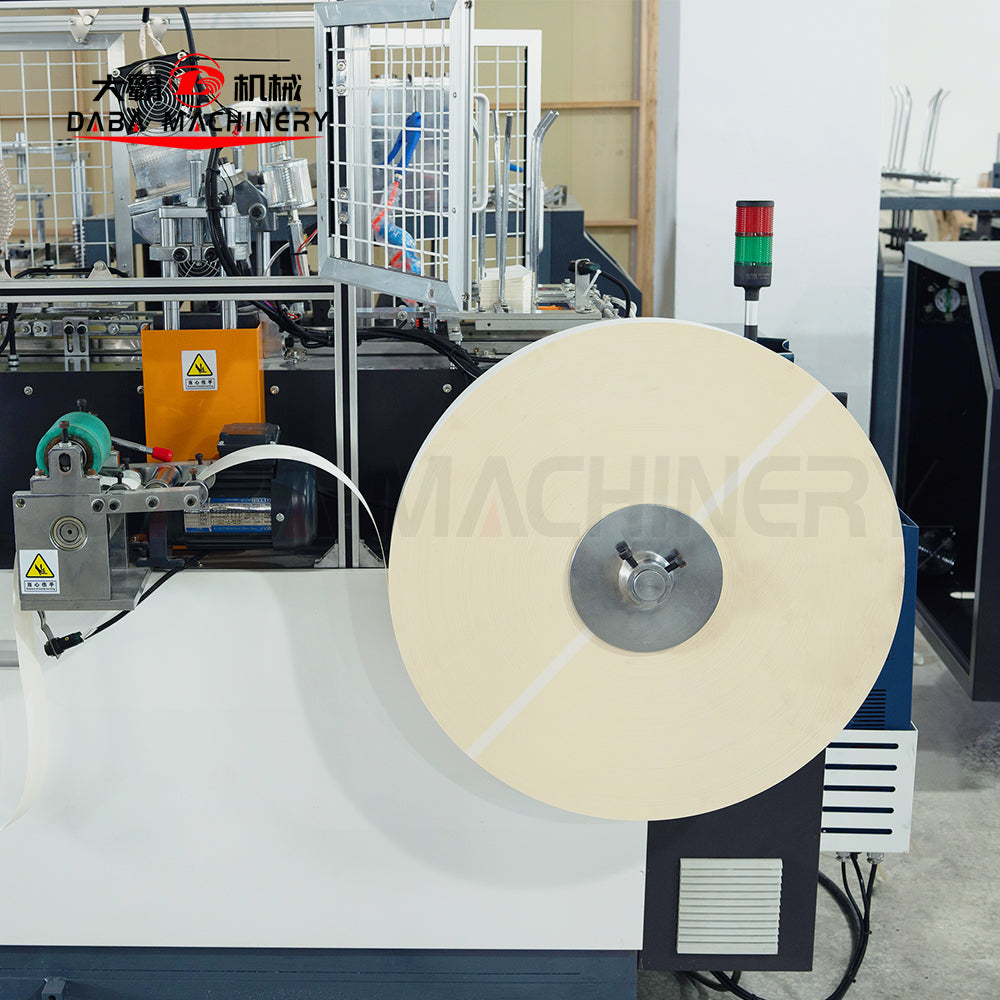

1. Paper Roll

Base raw material for paper cup production.

2. Printing Machine

Applies customized designs on paper rolls.

3. Printed Paper Roll

Printed rolls ready for die cutting.

4. Die Cutting Machine

Cuts printed paper into cup fan shapes.

5. Flat Sheet of Paper

Processed sheet material for next steps.

6. Waste Stripping Machine

Removes waste material and prepares clean cup fans.

7. Cup Fan

Paper segment prepared for cup forming.

8. Paper Cup Machine

Forms cup fans and bottom paper into cups.

9. Bottom Paper

Material used for forming cup bases.

10. Paper Cup

Completed paper cup ready for inspection.

11. Paper Cup Inspection Machine

Ensures each cup meets quality standards.

12. Double Wall Paper Cup Sleeve Machine

Adds insulating sleeve for double-wall cups.

13. Packing Machine

Packs cups for transportation.

14. Packaging Paper Cups

Final packaged products ready for shipment.

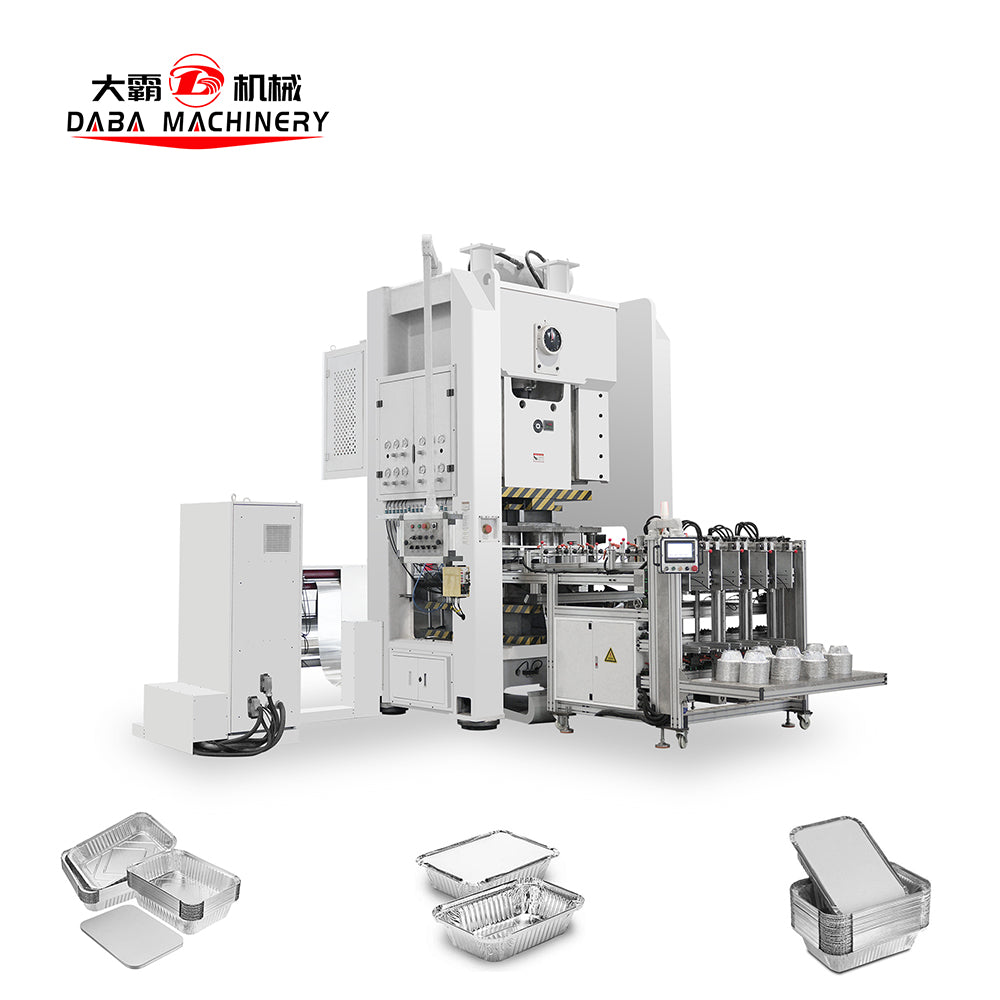

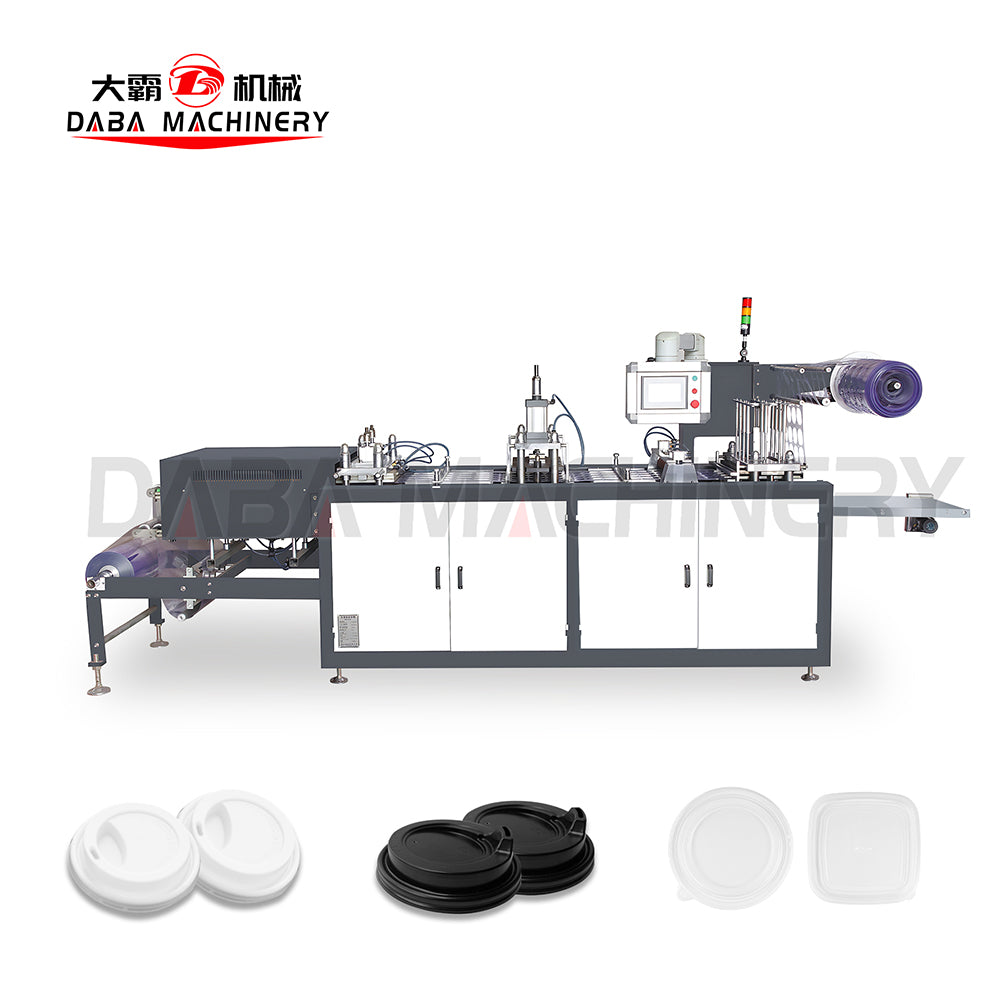

Popular Machine Recommendations

Contact Us

Message content including Country, Email. And What Do You Want?